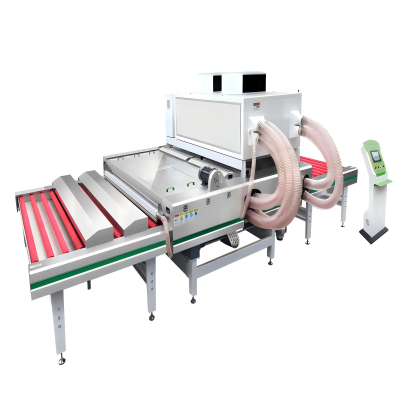

Double Glazing High Safety Warmth Soundproof Argon Gas Filling Machine

1). Stable performance with DELIXI pilot light, rotating switches, PLC and air-injecting sensor.

2). Automatic air-injecting indication and air-full indication as well as the automatic air-injecting stopping function.

3). Injecting gas into four pieces of glass at the same time.

4). Tight-style working system and easy operation.

Double Glazing High Safety Warmth Soundproof Argon Gas Filling Machine It has the following advantages and performance

1. Rotary Rubber-spreading Machine is the special equipment which seals insulating glass in the level position and apply with Two-component Extruder.

2. This machine is easy to operate. Place the glass on the rotating Table and the glass will be absorbed by the sucker.

3.Rotating through the foot-switch control, is very easy to seal.

4.Pressed down the gas foot-switch after the completion of sealant, the sucker would be released and the glass could be removed

Packing&Shipping

Plywood box or plastic film is ok for the insulating glass argon gas filling machine.Please tell us if you need any special labels on machine or package.

We can arrange the delivery with our agent or you could arrange it with your agent.And your requirement is also ok for delivery to the place where you have container.All is for your convenience.

FAQ

Best-in-class after-sales support: 1. Our commitment to your success does not end with your purchase. We mention Provide high-quality after-sales service to ensure that your equipment operates at its best without interruption. 2. Provide instructions and provide machine usage and installation videos (videos are provided in the customer's national language). 3. Provide video online guidance services and technical service groups. Customers can ask our technical service personnel if they have any questions during use. 4. For customers who are producing double-glazed glass for the first time and may not be familiar with the machine, we provide on-site installation services by technicians (customers are responsible for round-trip air tickets, meals and accommodation). The picture above shows our installers installing machines for customers in Dammam, Saudi Arabia.