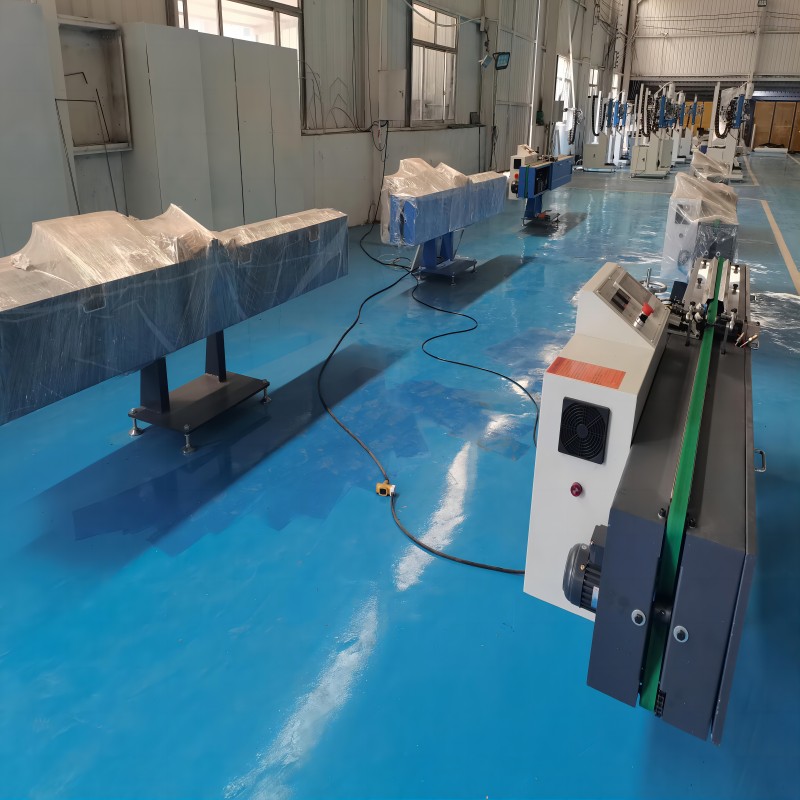

Automatic Butyl Extruder For IG Glass Production Line

1.Touch screen organic interface control system,the operation is more clear and simple.

2.The frequency conversion speed regulating system is adopted to make the speed from 15 to 35m/min with 1 to 5 gears option.

3.Take the lead in adopting advanced automatic glue mixing system,which can be adjusted arbitrarily within 6-18.5mm.

4.Rubber cylinder adopts rotary structure,0 to 90 degrees free rotation,putting glue,more convenient maintenance.

5.Adopt preheating system,arbitrarily set preheating time,improve efficiency.

6.Automatic alarm system for glue quantity,accurate display of glue quantity.

7.Using large size plastic cylinder,the amount of glue can be up to 14kgs.

Automatic Butyl Extruder For IG Glass Production Line.It has the following advantages and performance:

Automatic Butyl Extruder For IG Glass Production Line Its advantages and features:

Automatic Butyl Extruder is controlled by buttons.Digital Display system can show you the quantity of the glue automatically.Butyl spreading is well-proportioned and the linearity is good.Temperature and pressure can adjust automatically. Also can set the system pre-heat.Adopts the imported hydraulic and pneumatic supercharging system.The glue jar warning system will word when glue material is used up.Advanced device guarantees and best spreading effect on the arc aluminium frame.

Voltage: | 380V 50HZ |

Power: | 1.6KW |

Air pressure: | 0.5-0.8Mpa |

Air consumption: | 50L/min |

Transmit speed: | 0-35m/min |

Temperature: | 100-140°C |

Squeeze pressure: | 8-15Mpa |

Adjustable range: | 3-30mm |

Overall dimension: | 3500mm x 700mm x 1080mm |

Weight: | 630kg |