Automatic Desiccant Filling Machine

1. This machine is suitable for punching holes in the middle of the back of aluminum space for insulating glass,filling molecular sieve and automatically sealing glue,and filling under closed conditions,which solves the problem of water vapor absorption failure of desiccant and improves efficiency and service life of insulating glass.

2. Original technology can process multiple aluminum frames at the same time.

3. Equipped with LCD touch screen ,input machining data and start machining with one button .

Automatic Desiccant Filling Machine.It has the following advantages and performance:

1.Introduction of The Product

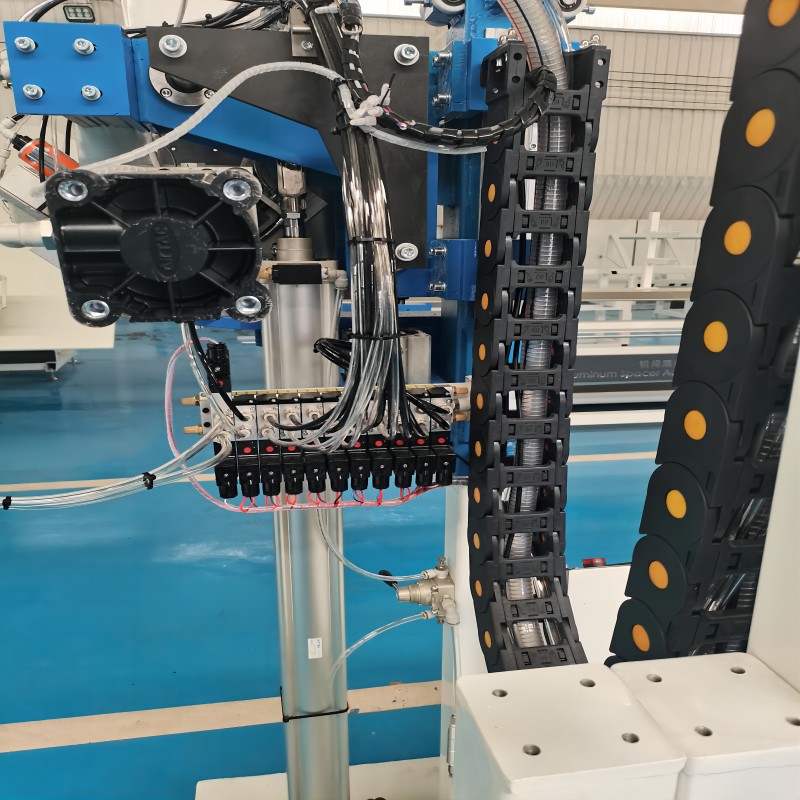

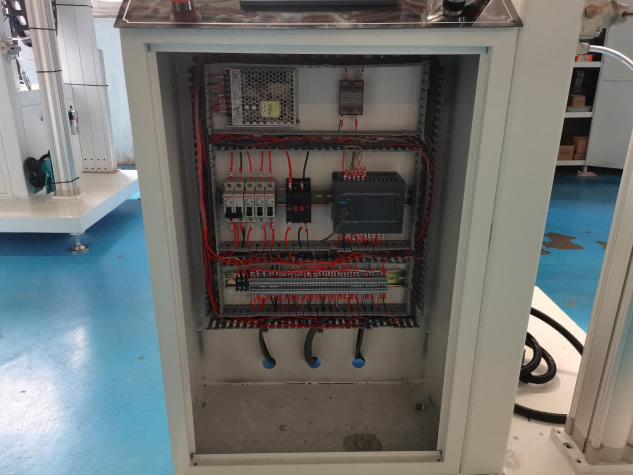

This machine has PLC control system,man-machine interface,easy to operate.Can be filled and automatically bent to form aluminum frames and ordinary straight-angle aluminum frames,Filling height can be adjusted according to the size of aluminum frame.Unique advanced feeding device,which can automatically replenish materials.Customized arc angle aluminum frame filling(such as high-speed rail glass).

2.Product Parameter Table

Voltage | 220V/50Hz |

Air pressure | 0.5-0.8Mpa |

Desiccant flow rate | About 24g/s |

Filling speed | 8-12s/pc(1*1m/9a) |

Total power | 0.8Kw |

Desiccant diameter | 0.5-0.8mm |

Max.Aluminum bar size | 3000*3000mm |

Min.Aluminum bar size | 350*350mm |

Specification for aluminum bar | 6.5*6.5--5.5*34.5mm |

Overall dimension | 900*1200*3600mm |

3.Product Packaging