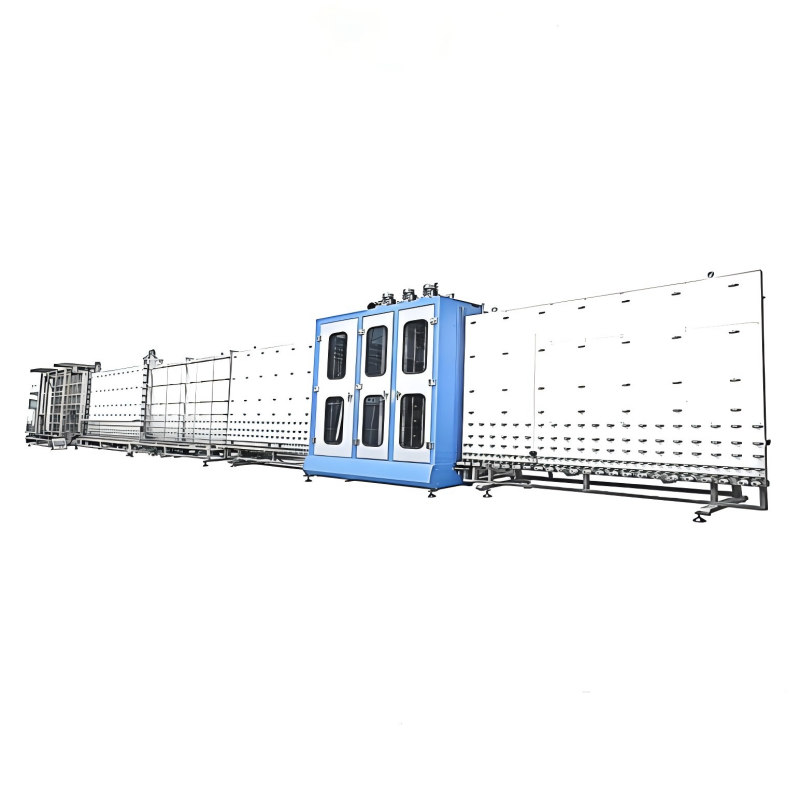

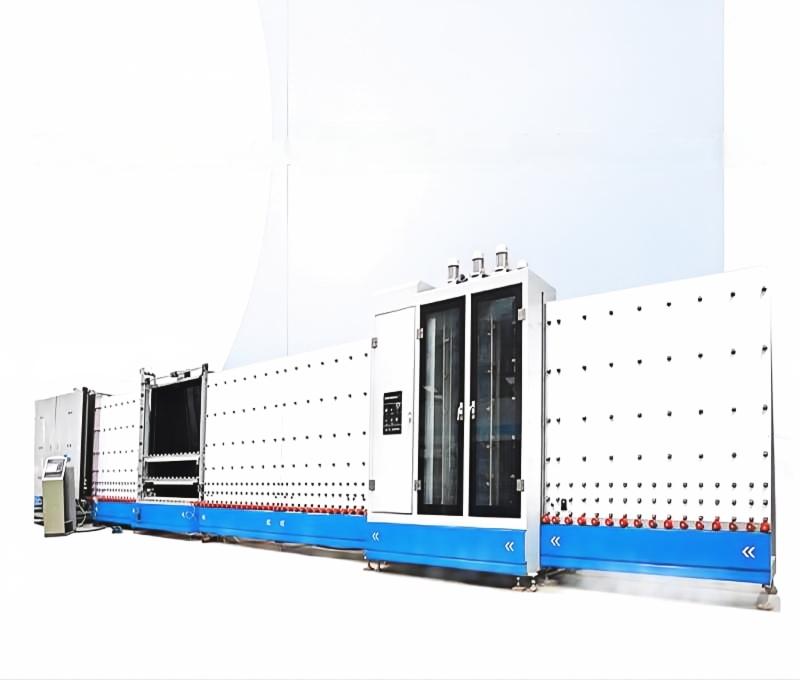

CNC Double Glazing and Triple Glazing Glass Production Line

1. This production line is an independent intellectual property rights that we independently developed.

2. All procedures, from washing to sealant, they are fully automatic. Completely controlled by the PLC system, simple operation, and humanization.

3. Consistent loading to ensure that the three or multilayered glass are in same position, same speed.

4. Washing inverter controls the brush to rotate, so that it can protect LOW-E glass.

5. Intelligent automatic spacer heating equipment, it only heat the spacer separately, automatically heat and the light is on when the glass come in to achieve efficient energy saving.

6. The multi-cavity insulating glass can be automatically pressed and inflated according to the set number of glass layers.

7. The semi-finished glass section can be automatically sealed online in the last procedure. By using our MBS (Multi-layered Butyl Spacer), finished glass does not need twice sealant.

CNC Double Glazing and Triple Glazing Glass Production Line.It has the following advantages and performance:

CNC Double Glazing and Triple Glazing Glass Production Line Its advantages and features:

1.Assembly with gas filling.

2.Automatic detection of Lowe glass, coated glass.

3.3 pairs of Low-e brushes.

4.Stainless steel air knife and sllencer cotton.

5.High and low speed conversion.

6.Automatic measurement of glass height and thickness.

7.Servo motor control far assembly.

PACKING:

1.For full container load, usually wrapped in stretch films.

2.For open top container load, put on top grade plastic overcoat and tarpaulin to protect the equipment from moisture and water.

3.For less than container load, iron frame fixed or standard export plywood case.

DELIVERY:

* Small and few machines: in 5-10 days after receiving pre-payment.

* Big or many machines: more than 25 days after receiving pre-payment.