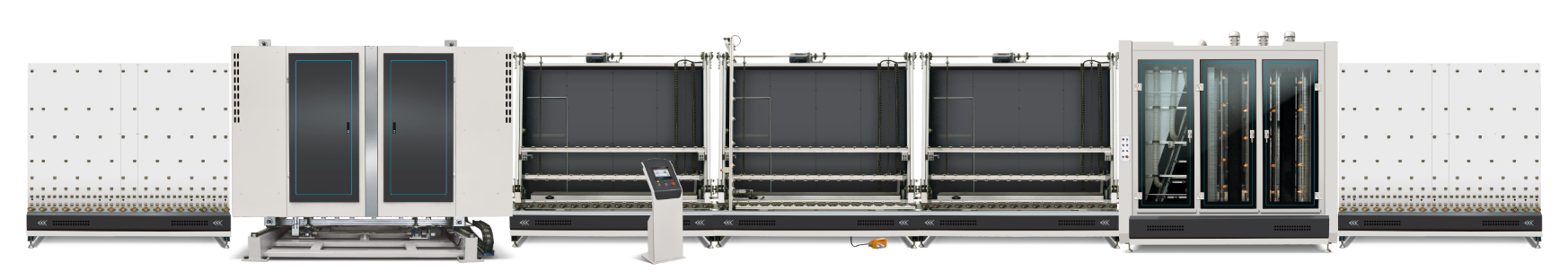

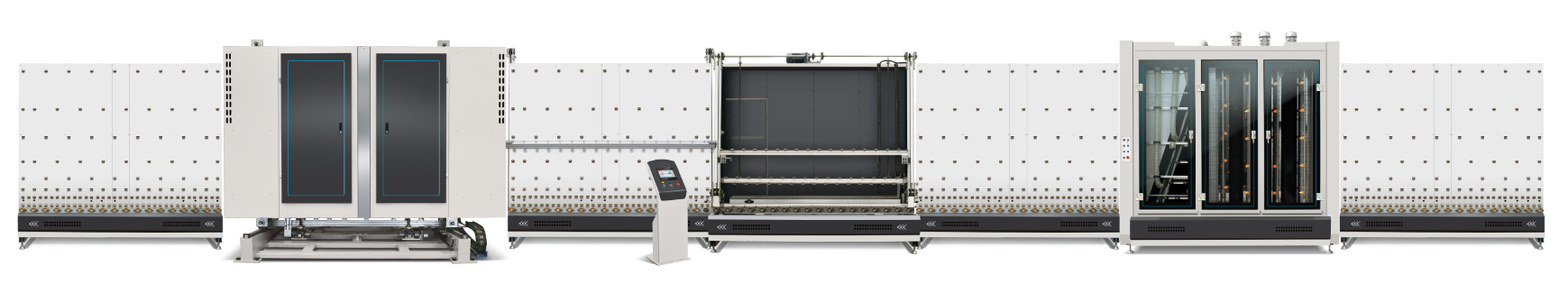

Automatic Gas-filled Insulating Glass Production Line

1. Automatic numerical control insulating glass production line,automatic LOW-E.

2. PLC control ,touch sensitive screen man machine interface.

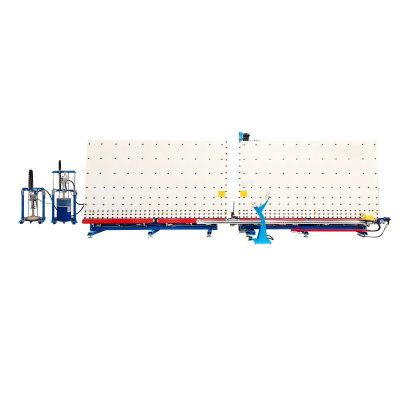

3. Adopt imported vacuum generator and sucker resulted in perfect suction effect to the glass.

4. Produce the Step IG Unit and three Piece IG production according to the customer’s different request.

5. Full distance automatic changeable frequency speed adjustment,which can save work waiting time and improve production efficiency.

Automatic Gas-filled Insulating Glass Production Line. It has the following advantages and performance: 1.Introduction of The Product

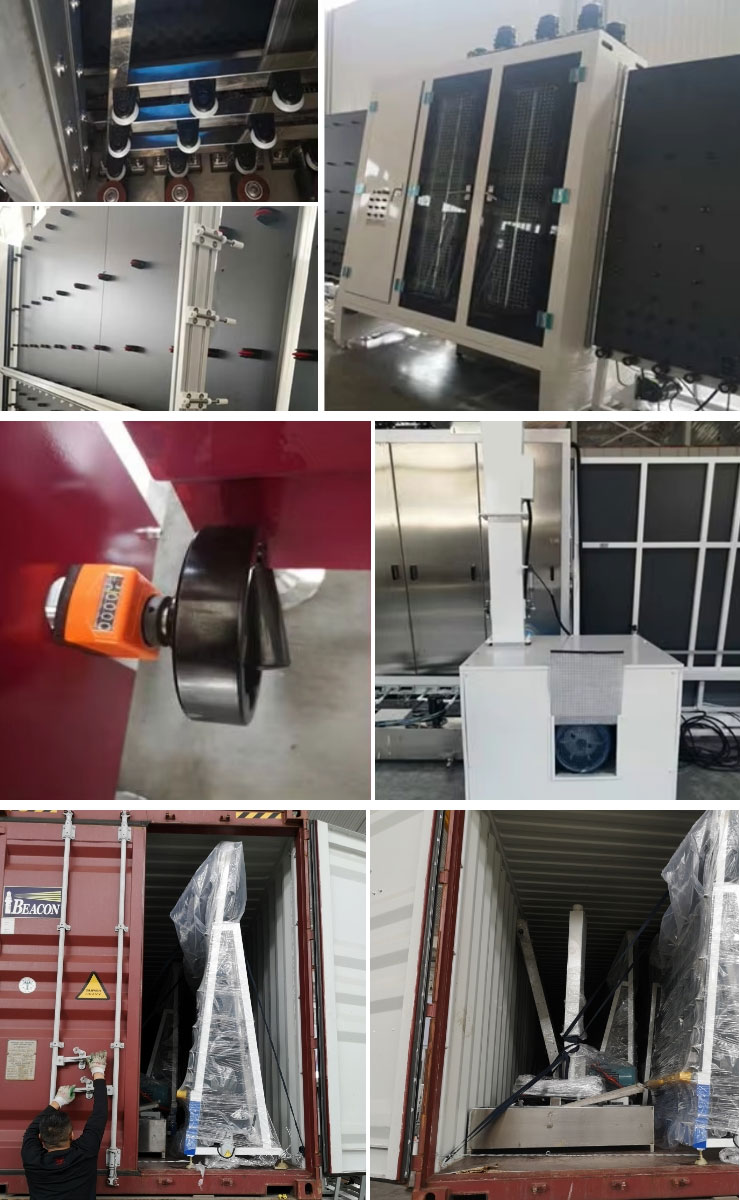

This machine is in-board inflatable,under the inflatable curtain,the concentration of national standards.Pressing bar with servo pressing,synchronous belt drive,smooth operation,even pressing.Microcomputer program Digital Control Production Line,save labor waiting time,improve production efficiency.Glass support,size plate positioning,follow the seal baffle are driven by servo motor,efficient and reliable.

2.Product Parameter Table

ITEM | LBG2500 | LBG2000 |

TOTAL POWER | 46KW | 36KW |

MAX GLASS SIZE | 2500*4000MM | 2000*3000MM |

MIN GLASS SIZE | 280*450MM | 280*450MM |

PANE GLASS THICKNESS | 3-12MM | 3-12MM |

MAX I.G UNIT THICKNESS | 12-40MM | 12-40MM |

GLASS WASHING SPEED | 2-12M/MIN | 2-12M/MIN |

WORKING SPEED | 2-45M/MIN | 2-45M/MIN |

AIR FLOW(AIR PRESSURE) | 0.8m3/MIN(1MPa) | 0.8m3/MIN(1MPa) |

TOTAL WEIGHT | 7000KG | |

OVERALL DIMENSION | 25300*3200*3600mm | 21000*3000*2910mm |