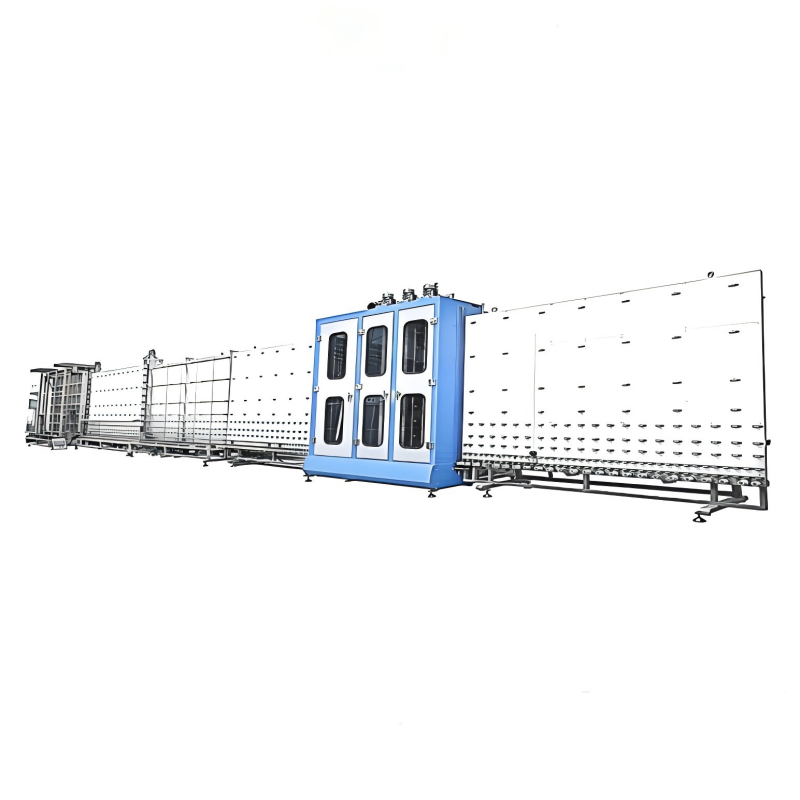

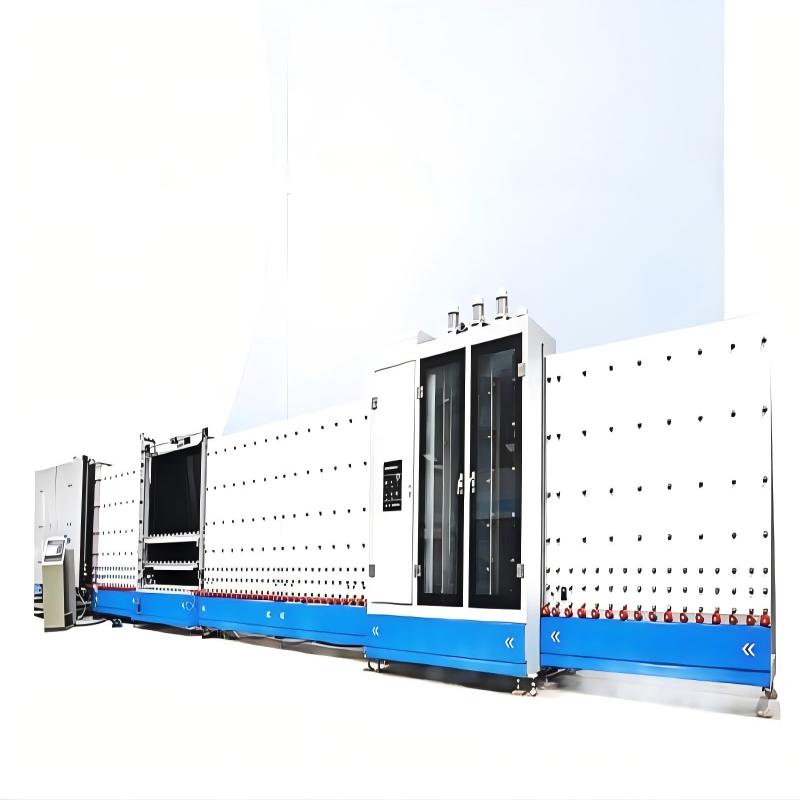

Double Glazing Glass Making Machine with Argon Gas Filling

1. This production line is an independent intellectual property rights that we independently developed.

2. All procedures, from washing to sealant, they are fully automatic. Completely controlled by the PLC system, simple operation, and humanization.

3. Two purposes on one machine, which can automatically produce flexible warm-edge hollow glass, on the other hand, it can meet the production of traditional groove aluminum hollow glass.

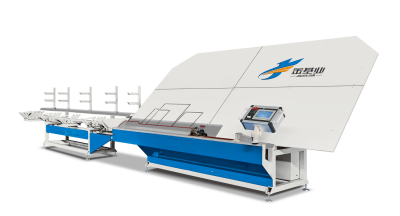

4. The patented Spacer Applicator, which uses a servo multi-axis linkage, and the glass rotation method quickly and accurately realizes the automatic upper entry. Improve product accuracy while improving production efficiency. To achieve the purpose of less labor and higher production capacity.

5. Consistent loading to ensure that the three or multilayered glass are in same position, same speed

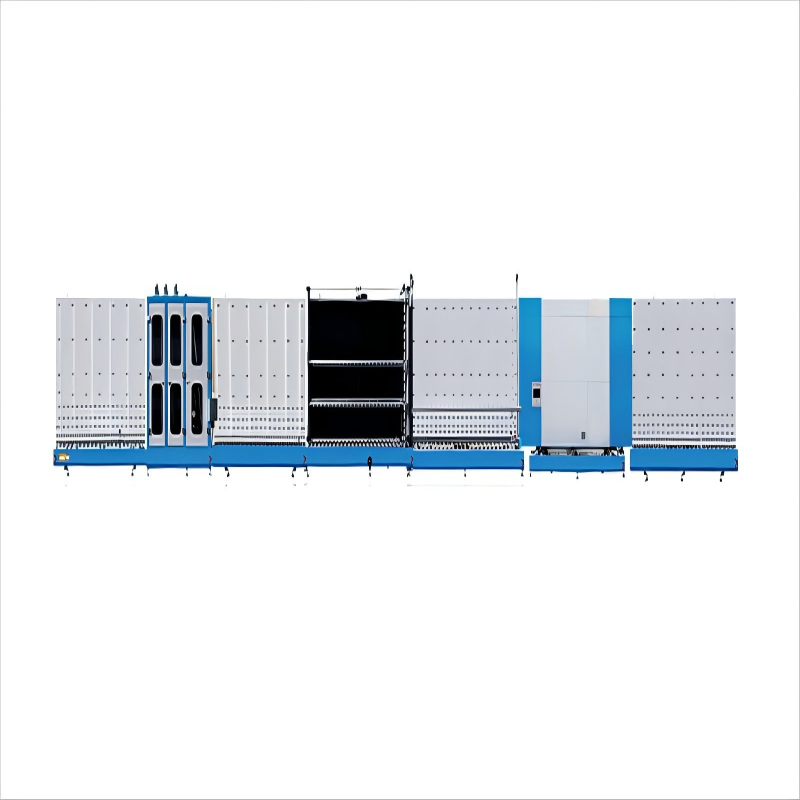

Double Glazing Glass Making Machine with Argon Gas Filling It has the following advantages and performance

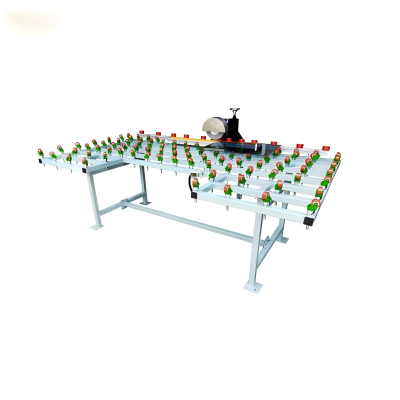

1、The cleaning area is completely made of stainless steel,which durable in use.

2、Equipped with auto identification system,can distinguish the common glass and coated or low-e glass.

3、Automatic cleaning and drying transfer structure designed for the cleaning of the glass thickness 3-12mm.

4、Three hair brush; Use three hair brush to ensure the best cleaning effect, the water tank is equipped with thermostatic water heating device.

5、Clean the drying section adopts the non-polar speed regulation, the glass can run smoothly at the right speed.

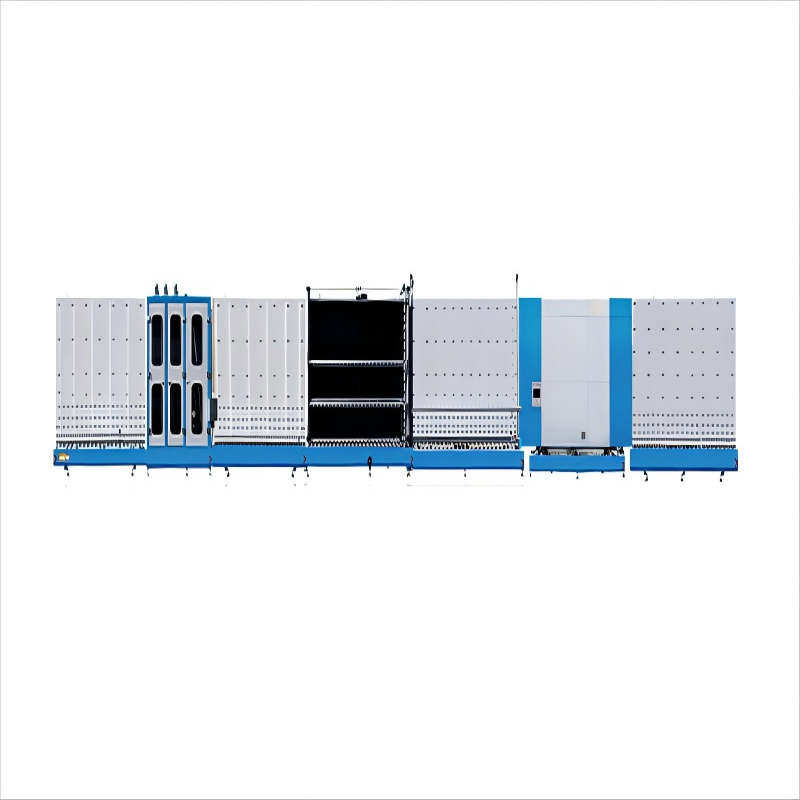

The infomration is as follows: | |

Lead-in conveyer: | 3000*800*3200mm(Length*Width*Height) |

Washing and Drying section: | 2200*1500*3600mm(L*W*H) |

Inspecting section: | 3000*800*3200mm(L*W*H) |

Unit thickness: | 3000*800*3200mm(L*W*H) |

Plate press section: | 3200*1500*3500mm(L*W*H) |

Tilting Table: | 3000*1100*3200mm(L*W*H) |

Main technique parameter: | |

max.working size: | 2200*3000mm |

min.working size: | 400*600mm |

glass thickness: | 3-19mm |

unit thickness: | up to 50mm |

glass washing speed: | 0-8m/min |

conveying speed: | 8-48m/min |

Brush: | 4pair(LOW-E) |

electronic power: | 3p 380v 50hz |

Power consumption: | 38kw |

Dimension: | 21000*2200*3600mm |

Pre-sale service

●Free contact for the most suitable machine

●Free professional design for each customer especially.

After sale service

●24 hours technical support by phone, email or skype

●1years warranty period

●Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.