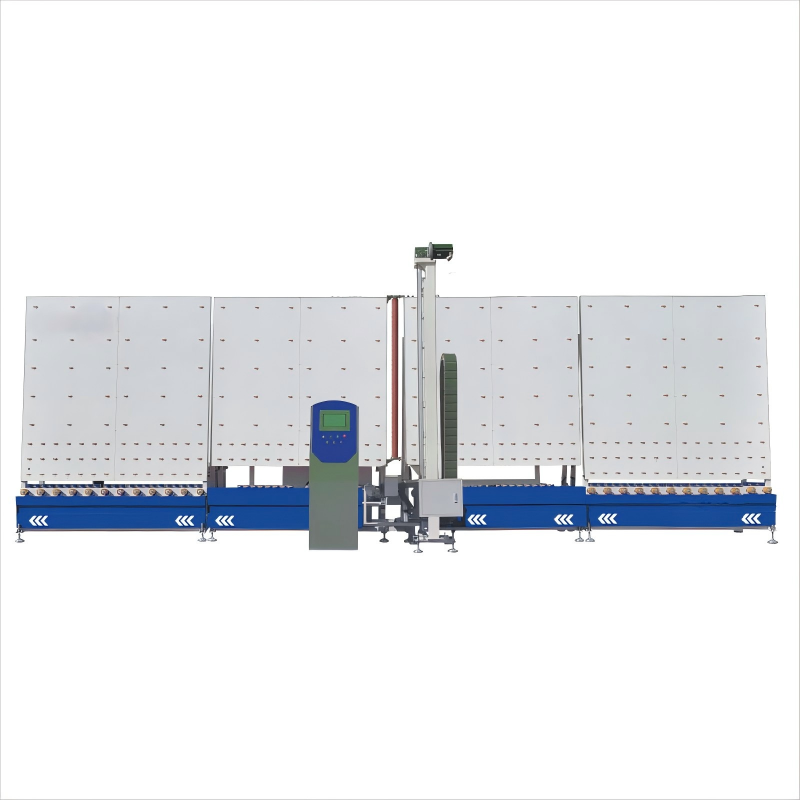

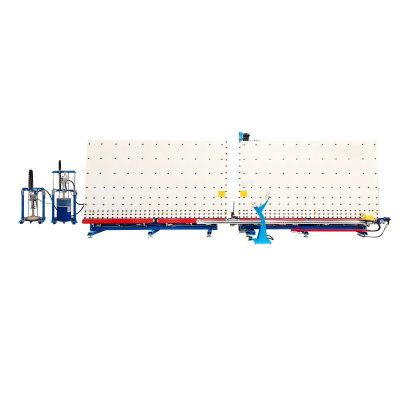

Vertical Automatic Low-E Coating Film Deletion Removing Machine

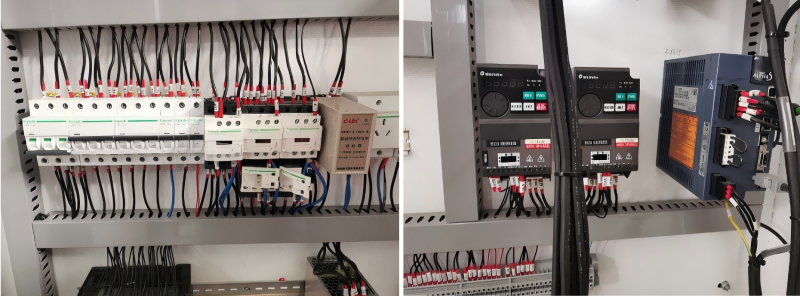

1) The automatic machine is equipped with a full servo convey system and Germany Simons control system.

2) It is capable of removing the scalene film with one operation. The deleting width for overlapped area is also adjustable

3) Manual operations are available for each function, useful in debugging and maintenance.

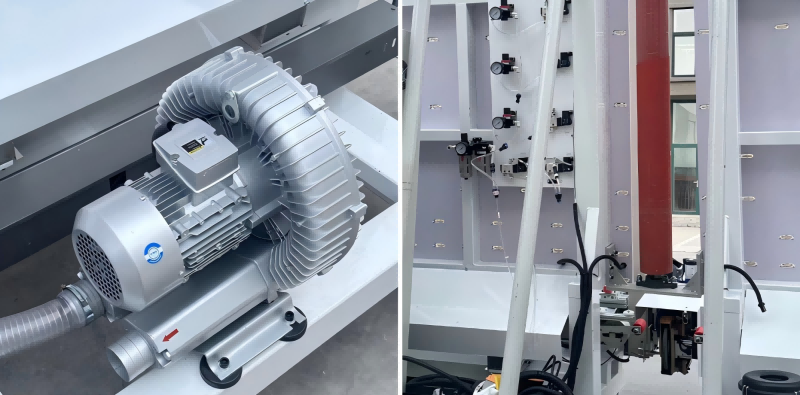

4) It is equipped with a dust suction device to mitigate dust pollution.

5) The input part and output part can be run asynchronously, improving productivity.

6) The stripping speed is adjustable (according to different film types and expected stripping effect).

7) Six servo motor control system and an adjustable linear dimension are supplied to guarantee a higher accuracy for arc / shapes.

8) The vertical low-e edge deletion machine can handle specially shaped glass panels, including the glass panels with holes for point-supported glass curtain wall system.

9) The stripping width tolerance is smaller than 1mm,the stripping efficiency is >90% (for reference).

Film Deleting Removing Machine,Low-E Coating Film Deleting Machine,Low-E Coating Film Removing Machine

1. Removable and temperable LOW-E glass and double silver film layer

2. All functions can be operated manually to meet debugging and emergency repair needs.

3. The grinding layer dust is equipped with an absorption device to reduce dust pollution.

4. The loading and unloading of segments can run asynchronously to improve production efficiency.

5. The grinding wheel can be mechanically trimmed to make grinding cleaner.

6. Both input and output are synchronous belts, which ensure smooth, fast and wear-resistant transmission.

7. The film removal speed is adjustable and can be adjusted according to the film type and film removal effect.

8. Controlled by six servo motors, the size is linearly adjustable to ensure accuracy.

9. Automatically synchronize with the production line to save time and labor

10. The grinding wheel feed is automatically controlled by the motor to avoid grinding wheel wear and adjustment or grinding to the rubber roller.

11. Special-shaped and point-type curtain wall perforated glass can be ground according to the picture gallery

12. The overlapping width of the processing of large and small pieces of glass can be adjusted to ensure that there is no

residual film layer in the middle, and it can be completed at one time. The film can also be removed multiple times to make

the film removal effect better.

13. The film removal width error is less than 1mm, the film removal is uniform, without ripples, waves, filaments, etc.

Q: How to choose the suitable machine?

A: Send us the effect you want, we'll advise based on 17+ years' experience.

Q: How to operate the machine?

A: Detailed Manual and operation videos will be provided, easy to operate.

Q: Delivery time?

A: 3~4 weeks after getting deposit.

Q: Warranty time?

A: Machine 1 Year,Laser source 2 Years.

Q: After-sale service time?

A: At your working time, we have different teams covering all time zones.