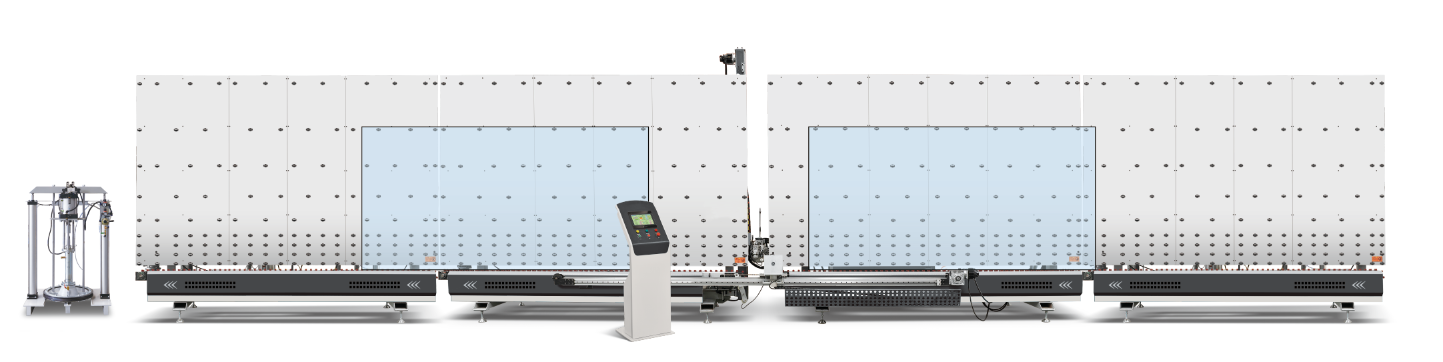

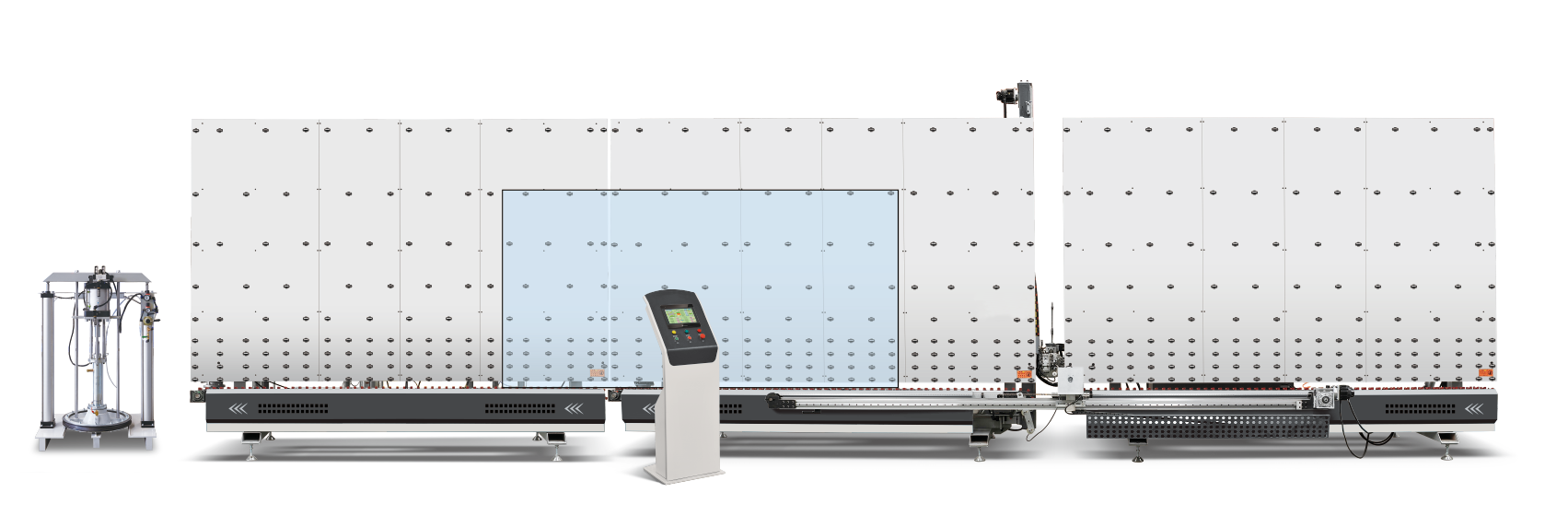

Automatic Insulating Glass Sealing Machine

1. High sealing performance,high automation,reduce labor cost,save manpower cost,improve production efficiency.

2. Fully intelligent and smart HMI in Touching Screen,with memory function and easy operation.

3. Best sealing quality without air bubbles,smooth surface,avoid time for corner correction.

4. The width of machine is 1.4m,small floor area ,save space.

5. The section is one production line,it can prestore three pieces glass to improve the efficiency efficiently.

6. The smallest insulating glass size can be processed is 300*300mm.

Automatic Insulating Glass Sealing Machine.It has the following advantages and performance: 1.Introduction of The Product

Special V type transmission belt to avoid the sealant sticking on the belt, ensure the glass edge clean ,V type Block is changeable . The spare parts are produced with high standardization and high precision, ensure the machine can be used with long-term stability Suitable for triple glazing . Conveying wheel on backboard adopts embedded wheel ,to make sure the glass be transported smoothly Equipped with high speed positioning function ,glass can be located accurately when transport fast .Keep machine service and upgraded timely with our own R&D departments 20 years experience in extruding systems to make the system more stable .High pressure non-return valve to make the washing speed faster,save sealant and avoid blocking All low-voltage appliance adopt France Schneider to make the performance stable.

2.Product Parameter Table

Model | ZNJ2025-I | ZNJ2540-I |

Voltage power | 380V 7KW | 380V 9KW |

Air pressure | 0.6-0.8MPa | 0.6-0.8MPa |

Squeeze pressure | 32MPa | 32MPa |

Max. Glass size | 2000*2500mm | 2500*4000mm |

Min. Glass size | 300*300mm | 300*300mm |

Glass thickness | 12-56mm | 12-56mm |

Working Speed | 5-40m/min | 5-40m/min |

Overall dimension | 8030*1400*2950mm | 8630*1400*3500mm |