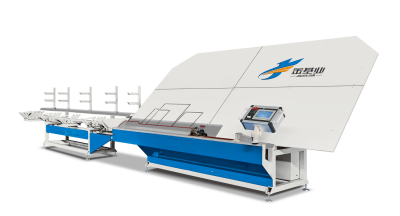

Two Component Sealant Extruder Machine

1.The synchronizing linkage match structure can be adjusted conveniently.

2.The acicular one-way value ensures mixture not to reflow, avoiding rohrinnere solidification.

3.Totally-enclosed firming agent glue-way system, preventing firming agent from meeting air.

4.Sensitive high-pressure protective value makes the operation in safe condition.

5.Gas boost drive has the performance of stable pressure and evenly glue extruding.

6.Adopt international popular static reciprocating-type mixer to mix more evenly.

Two Component Sealant Extruder Machine. It has the following advantages and performance: 1.Introduction of The Product

This machine is produced with the best technology in China and abroad. Used for coating sealant for the second seal of insulating glass.Unique convenient adjustable ratio, guarantee the accurate sealant ratio upon to highest requirements.Sealant extruding is continuous and even with good sealing finish, high efficiency.

2.Product Parameter Table

Parameter | |

Mixing ratio | 6:1~14:1 |

Base bucket | 55 gallon(200L) |

curing agent bucket | 5 gallon(20L) |

Max. Air consumption | 0.8m3/min |

Glue airpressure ratio | 50:1 |

Max. squeezing glue pressure | 29Mpa |

Air supply pressure | 0.5-0.8Mpa |

Oversize | 1100*950*1630mm |

Gross Weight | 800KG |