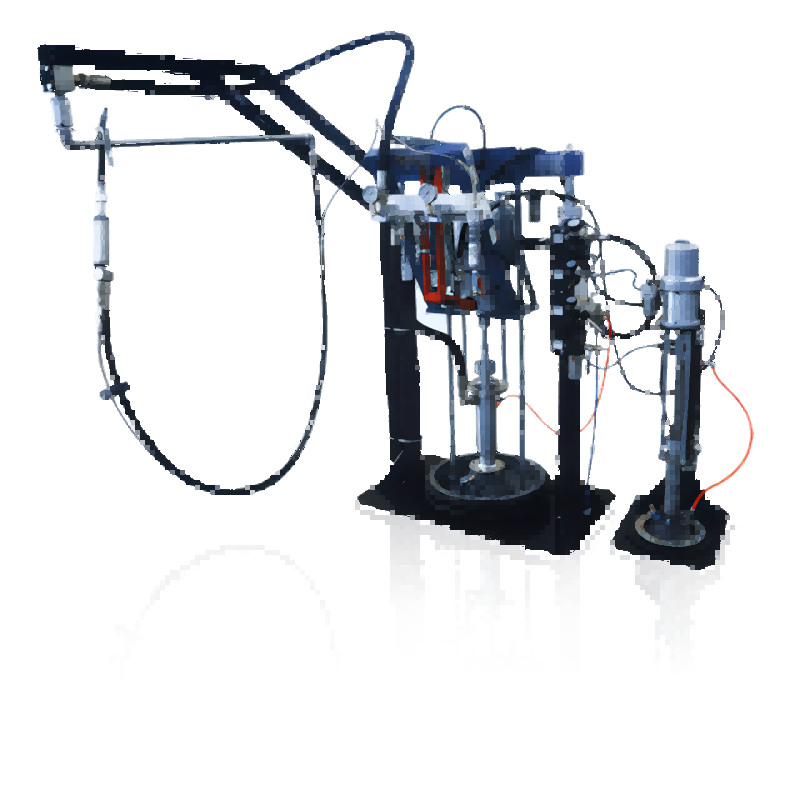

Vertical Manual Glass Sealant Extruder Machine

1)It is produced with best technology in China and abroad Used for coating sealant for the second seal of insulating glass with aluminum spacer.

2)A(White) and B(Black) component sealant pump use Korean original pneumatic system, reversing sensitive and reliable 3)Unique convenient adjustable ratio, guarantee the accurate sealant ratio upon to highest requirements.

4)Anti-back flow control structure.

5)Mixed rate detector can control the rate of A and B group sealant

6) Sealant extruding is continuous and even with good sealing finish,high efficiency

Vertical Manual Glass Sealant Extruder Machine Its advantages and features:

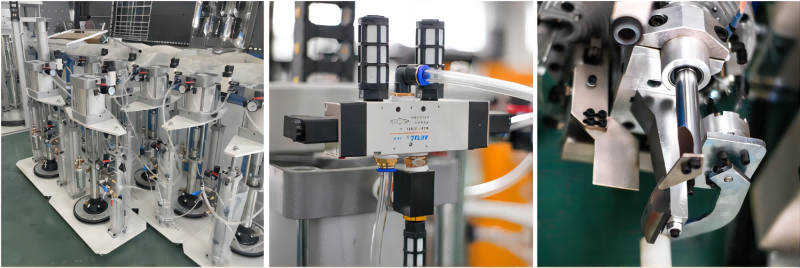

1.Glue pump: A,B group have their pump respectively,drived by hydraulic cylinder, and make movement back and forth.then inhaling glue and make it out..A,B gule pump is connected with pressing glue and glue plate,then link together with the rack.

2.A,B ratio of the components separately control A,B groups to achieve.The range of glue amount is bif,also easy operation.

3. Hydraulic system: A, B driving force comes from the hydraulic system, A, B group are located in a plastic pump air movements, movements of the body by two cylinders of parallel and Beams through the body of their respective fixed link, one of its purposes is to be closed to the surface through the press of two-cylinder.The pressure from the size of adjustment clamps.: Second, when the need for plastic barrels, the cylinder Pressure can be set against. Leave the plastic barrels, to replace the new plastic barrels.

4.The control box: it have electronic, hydraulic, pneumatic and electrical components, control switch is on the panel.

5. The control box is equipped with "exigency stop switch," running in the event of a failure, should be "exigency stop switch" button, emergency shutdown,can use again after the trouble solved.

Model | JYT-03 | JYT-08 |

Mixing ratio | 6:1~14:1 | 6:1~14:1 |

Material drum | 55gallon(200L) | 55gallon(200L) |

Curing agent drum | 5gallon(20L) | 5gallon(20L) |

Max.air consumption | 0.8m³/min | 0.8m³/min |

Max.dispensing pressure | 30Mpa | 30Mpa |

Output | 4~10L/min | 4~10L/min |

Air supply pressure | 0.6~1.0Mpa | 0.6~1.0Mpa |

Outside dimension | 1100*950*1980mm | 1420*900*2500mm |

Weight | 650Kg | 650kg |

1.For big machine and full container load, usually wrapped in stretch film.

2.For open top container load, put on top grade plastic overcoat and tarpaulin to protect the equipment from moisture and water.

3.For less than container load, iron frame fixed and standard export wooden case for optional.