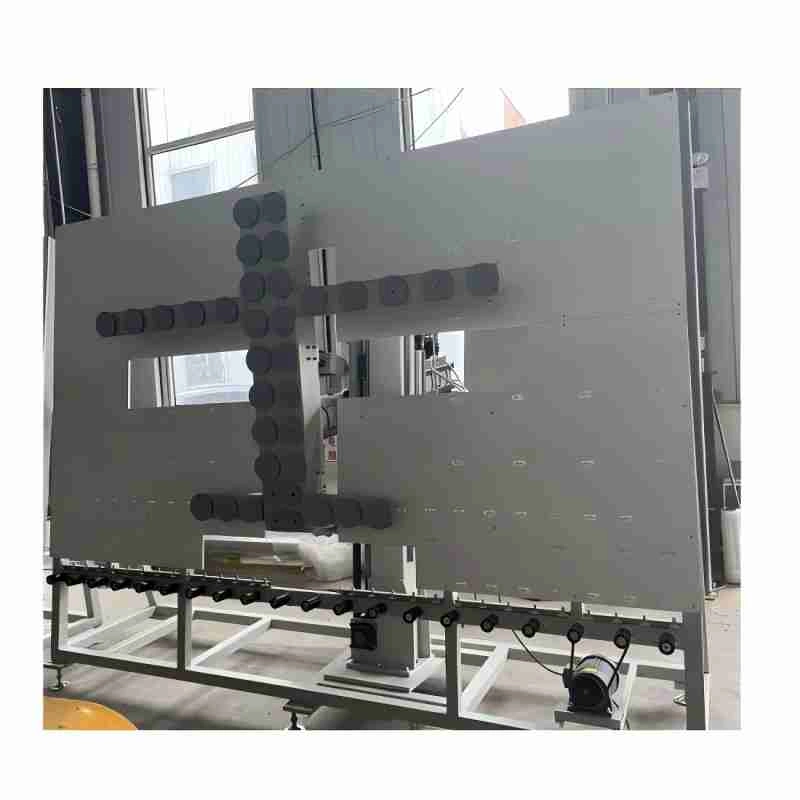

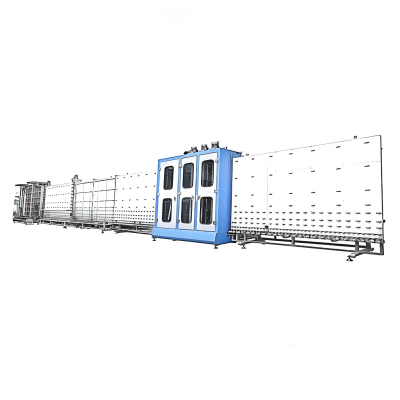

Automatic Vertical Glass Loading Machine

1.Servo motor is used to overturn, which can stop at any angle, and the running speed is stable, which can meet the loading/off-loading operation of 10~55mm thickness glass.

2.The vertical direction can be adjusted from 0 to 15 degrees, which can meet the requirements of glass shelf loading at various angles.

3.It can meet the loading depth within 700mm, and can be loaded directly from the glass frame without any auxiliary frame.

4.The sucker adopts an advanced double-layer adsorption structure (inner and outer layers), which makes the sucker firmer during adsorption operation and eliminates the defect of air leakage caused by scratches on the outer layer of the sucker.

5.With a unique lifting program device, the glass can be effectively sliced.

6.Using color LCD touch screen display interface, the operation is convenient and fast.

Automatic Vertical Glass Loading Machine.It has the following advantages and performance

Automatic Vertical Glass Loading Machine.It has the following advantages and performance:

* Servo motor is used to overturn, which can stop at any angle, and the running speed is stable, which can meet the loading/off-loading operation of 10~55mm thickness glass.

* The vertical direction can be adjusted from 0 to 15 degrees, which can meet the requirements of glass shelf loading at various angles.

* It can meet the loading depth within 700mm, and can be loaded directly from the glass frame without any auxiliary frame.

* The sucker adopts an advanced double-layer adsorption structure (inner and outer layers), which makes the sucker firmer during adsorption operation and eliminates the defect of air leakage caused by scratches on the outer layer of the sucker.

* With a unique lifting program device, the glass can be effectively sliced.

* Using color LCD touch screen display interface, the operation is convenient and fast.

Max glass size |

Q1: What kind of product you supply?

A:Beverage filling machine for water,juice,carbonated beverage and etc;packing system;water treatment system;PET bottle blowing machine,etc.

Q2: Where is your factory located? How can I visit your factory?

A: We are located in Zhangjiagang city, it is near to Shanghai and Wuxi. You can fly to Shanghai airport or Wuxi airport,we can pick you up from the airport or your hotel.

Q3: About installation?

A: We will send one-two engineers to your factory, to install the machines and train your staff how to operate the machines,it usually take 10 days to 25 days.

Q4: Which country do you export your machines already?

A; J&D have exported bottling and associated equipment to the USA,UK,Ireland,Canada,Australia,Mexico,Russia,Africa.