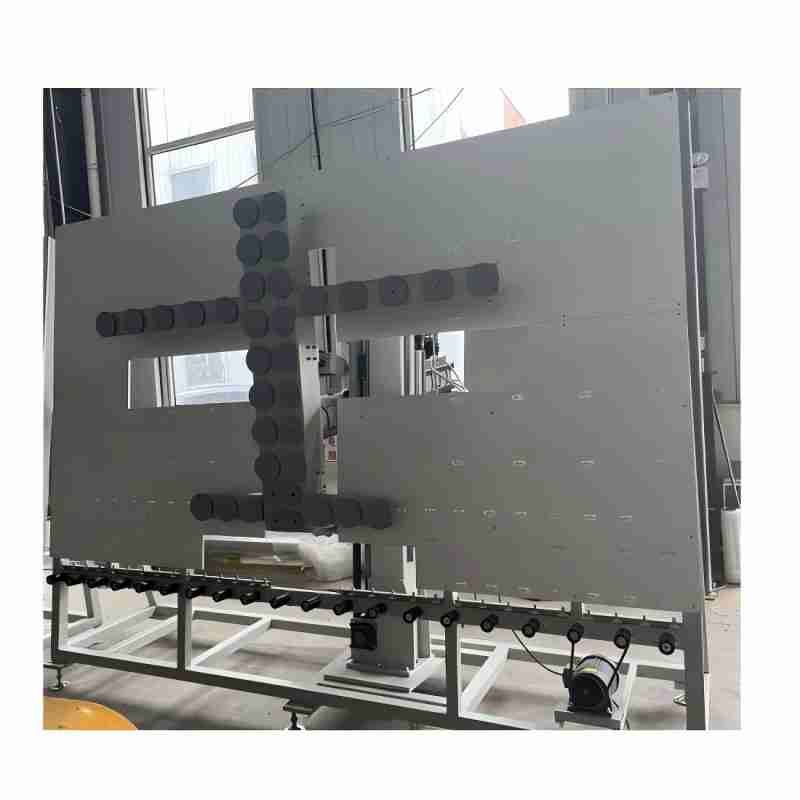

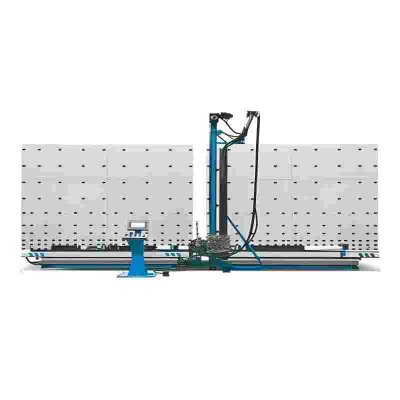

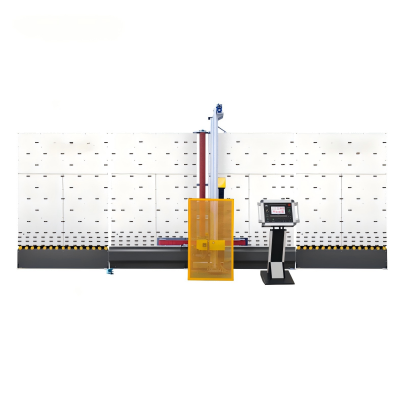

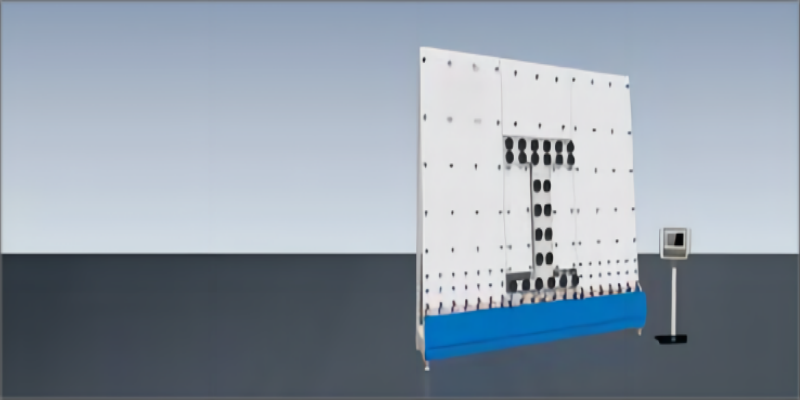

Vertical Loading Machine for IG Glass Production Line

1. It adopts Mitsubishi PLC control,10 inches touch screen.the dynamical system adopts 3 servo motor drive,it is easy to operate.the putting way for glass is of common putting,up/down putting;

2. The V belt can automatically adjust to the center position of glass thickness;The motor drives ball screw of reduction gear to adjust the V belt.The displacement sensor inducts the original point,and move on the liner track;

3. The machine-head automatically goes up to the glass height,if glass size is too small,it is not necessary to go up;the servo motor drives the reduction gear by chain sprocket on the liner track to make the machine head up/down,so that it can accurately the needed height;

4. it can connect with the automatic sealant line,automatic sealant sealing line date will be transfer to glass unloading machine

5. glass unloading machine can measure how many pieces glass it will put in one glass.Once glass plate is full,it will send an alarm

Automatic Insulating Glass Unloading Machine is a patented product which is excessive diploma of automation, saving manpower and improves manufacturing protection and efficiency. This computer adopts PLC to manipulate servo motor, photoelectric swap detects unique glass measurement automatically. It would not want to enter glass dimension manually. It can computerized runs, sucks glass, calculates going for walks distance. When glass shelf is empty, it will supply an alarm to remind employees exchange it.

PLC/servo motors |

Best-in-class after-sales support: 1. Our commitment to your success does not end with your purchase. We mention Provide high-quality after-sales service to ensure that your equipment operates at its best without interruption. 2. Provide instructions and provide machine usage and installation videos (videos are provided in the customer's national language). 3. Provide video online guidance services and technical service groups. Customers can ask our technical service personnel if they have any questions during use. 4. For customers who are producing double-glazed glass for the first time and may not be familiar with the machine, we provide on-site installation services by technicians (customers are responsible for round-trip air tickets, meals and accommodation). The picture above shows our installers installing machines for customers in Dammam, Saudi Arabia.