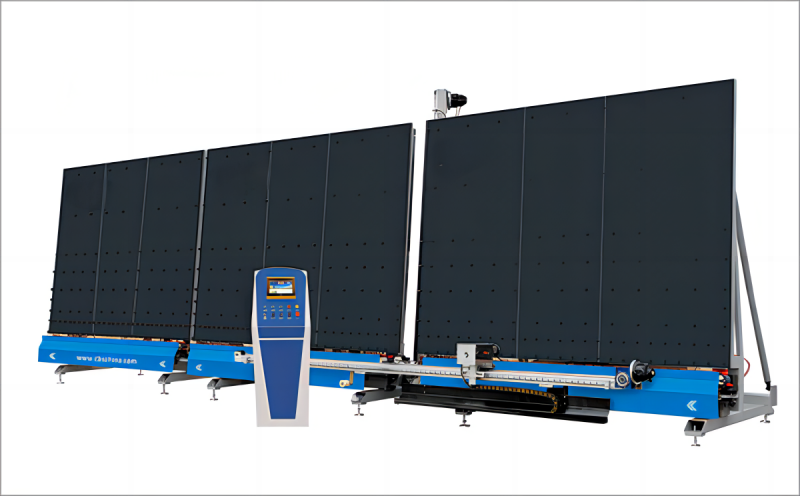

CNC Automatic Insulating GLass Sealing Machine

1 this sealing line is divided into 3 parts and seal double glazing and triple glazing

2 can keep insulating glass automatic continuously sealing, sealing with high efficiency

3 double sealant supply system(can seal silicone and polysulfide sealant)

4 adopted YASKAWA servo control system, motion controller and controller card, performance is stable, besides we adopt 6 axis servo motor,6 drives to make machine run with high precise.

5 glue nozzle can seal the middle of the spacer bar to make seal even and full

6 pecise adjustment for the mixing ratio of the sealant.

7 can measure the depth of extruding sealant and then adjust sealing speed.

8 measure insulating glass thickness automatically and then adjust belt V position to make sure working height

9 photoelectric can scan the glass size automatically

10 we will input all parameter in color touch screen in advance which is so convenient and easy to operate

CNC Automatic Insulating GLass Sealing Machine.It has the following advantages and performance:

CNC Automatic Insulating GLass Sealing Machine Its advantages and features:

The equipment is suitable for large-scale production enterprises, high production efficiency, reduce labor intensity,our company has a high quality and efficiency group to innovation more advanced technology production.Until now,we have got the CE and SGS,in the future,we will try our best to provide the better production.

The device is configured to three segments, divided into input, output, waiting for the next fragment,to achieve uninterrupted production,was controlled by the MP2000(motion controller) come from the Japan.